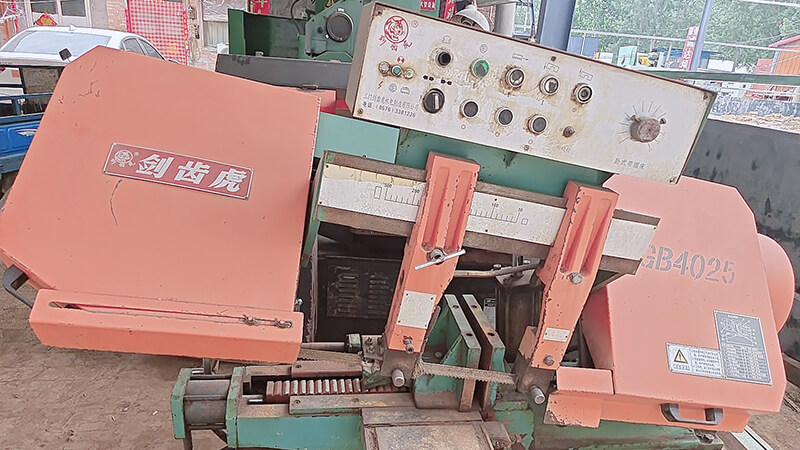

Second-hand GZ4232A sawing machine

Introduction to GZ4232A Bandsaw Machine

Performance Parameters

- Cutting Capacity: It can cut materials with a maximum size of 320mm×320mm. For round materials, the maximum cutting diameter is 320mm.

- Blade Linear Speed: Multiple blade linear speeds are available, typically 30/46/58/83m/min, which can be adjusted according to different materials and cutting requirements.

- Blade Specification: The commonly used blade specification is 1.1mm×34mm×4115mm (thickness × width × length).

- Motor Power: The main motor power is 4.0kW, the hydraulic motor power is 0.75kW, and the cooling motor power is 0.04kW.

- Overall Dimensions: The approximate overall dimensions of the machine are 2200mm×2200mm×1350mm, requiring a certain amount of space for installation and operation.

5,000.00$

| Category | Attributes | Details |

|---|---|---|

| Cutting Capacity | Maximum cutting size (square) | 320mm × 320mm |

| Maximum cutting diameter (round) | 320mm | |

| Blade Parameters | Blade specification | 1.1mm (thickness) × 34mm (width) × 4115mm (length) |

| Blade linear speed | 30/46/58/83 m/min (adjustable) | |

| Motor Power | Main motor | 4.0kW |

| Hydraulic motor | 0.75kW | |

| Cooling motor | 0.04kW | |

| Dimensions | Overall machine size | 2200mm × 2000mm × 1350mm (length × width × height) |

| Structural Design | Frame structure | Dual-column design (stable and low-vibration) |

| Clamping system | Hydraulic double clamp (strong and stable clamping force) | |

| Blade guide device | Guide arms + guide heads (ensures high perpendicularity of cuts) | |

| Control System | Operation mode | CNC control with touch screen + button dual control |

| Parameter setting range | - 5 groups of processing dimensions - Feeding length per group: up to 50,000mm - Processing quantity per group: 1–999 pieces | |

| Functional Features | Safety protection | Automatic stop on blade breakage; automatic stop when cutting is completed |

| Chip & cooling system | Automatic chip removal device; circulating cooling system (for blade and hydraulic oil) | |

| Feeding accuracy | Equipped with magnetic grid ruler (high positioning precision) | |

| Application | Applicable materials | Ferrous metals (carbon steel, alloy steel, stainless steel, etc.) and non-ferrous metals |

| Suitable scenarios | Die steel cutting, small-to-medium batch blanking of solid materials, profiles, and bundled small parts |

Don’t miss your opportunity-our best machines go fast.