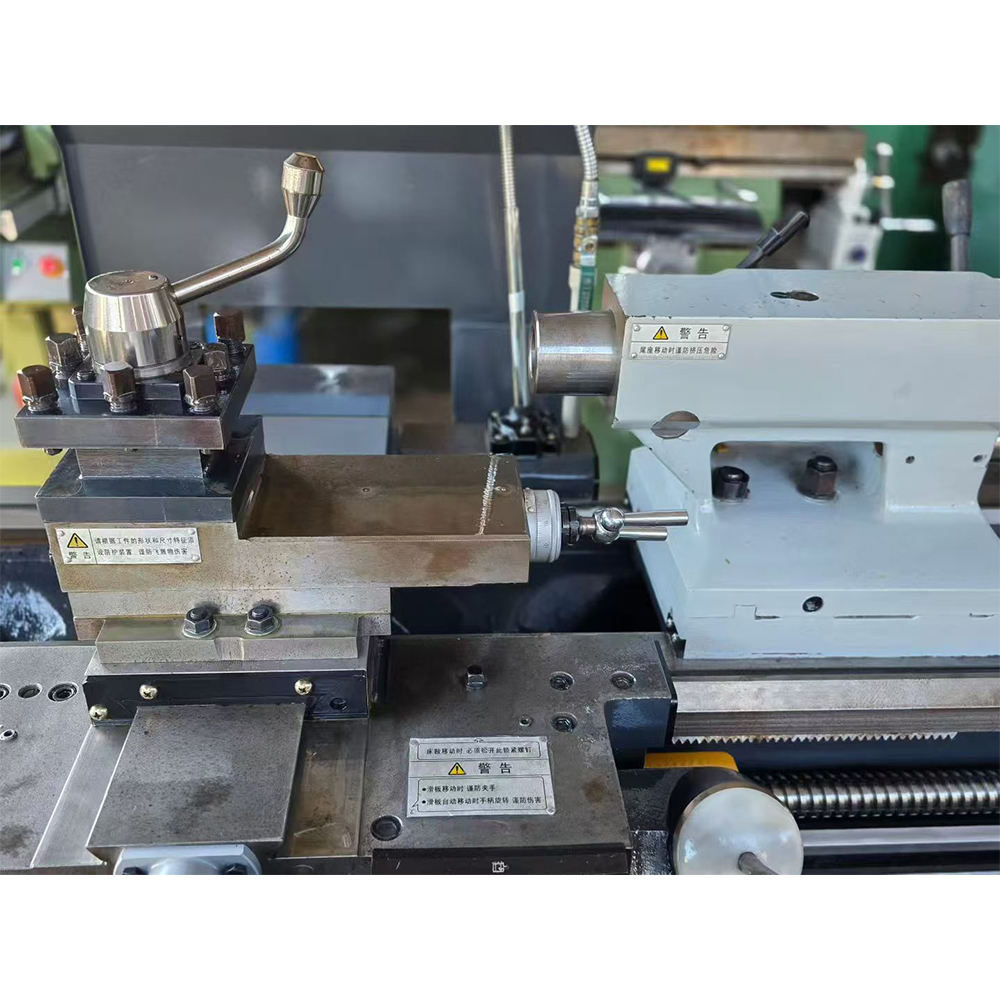

Baoji CS6150B lathe

Core Application Scenarios

The Baoji CS6150B lathe is an upgraded heavy-duty horizontal engine lathe from Baoji Machine Tool, a reputable manufacturer with decades of experience in China’s machine tool industry. As an enhanced version of the classic CS6150 model, it optimizes precision, power, and load-bearing capacity, while retaining the advantages of stability and easy operation. It is specifically designed for processing medium to large-sized, high-precision rotating workpieces, making it an ideal choice for small and medium-sized enterprises, heavy machinery workshops, precision processing facilities, and maintenance bases.

- Medium to Large-Sized Precision Parts Processing: With a maximum swing diameter of 500mm and an optional spindle bore of 100mm, the CS6150B excels at turning shafts, sleeves, flanges, discs, and other core components used in construction machinery, agricultural equipment, automotive chassis, and industrial instruments. It can efficiently process thick-walled workpieces and high-strength materials, achieving dimensional tolerance ±0.01mm and surface roughness Ra ≤1.2μm, meeting the requirements of precision manufacturing.

- High-Precision Thread Machining: Equipped with a high-precision ground lead screw and a multi-stage gear transmission system, it can accurately process metric, inch, trapezoidal, and triangular threads with a wide range of pitches. This makes it suitable for manufacturing large bolts, nuts, threaded shafts, and other fasteners used in mechanical assemblies, ensuring tight thread fit and reliable load-bearing performance.

- Small to Medium Batch Production: The 11kW high-power main motor provides strong cutting torque, and the optional hydraulic tool post reduces tool change time, significantly improving processing efficiency. It adapts to both single-piece trial production and small to medium batch processing, meeting the flexible production needs of industries such as machinery manufacturing, hardware processing, and auto parts.

- Heavy Equipment Maintenance and Repair: As a versatile heavy-duty lathe, it is an indispensable tool in maintenance workshops. It can repair worn parts such as large shafts, rollers, and gear sleeves, and fabricate custom replacement components, ensuring the smooth operation of production equipment. Its robust structure and flexible processing capabilities make it suitable for on-site or workshop-based maintenance.

Batch Advantages of Equipment

- Upgraded Precision and Stable Performance: The CS6150B adopts a reinforced box-type cast iron bed with excellent rigidity and vibration damping, ensuring stable operation during heavy cutting. High-precision spindle bearings and a ground lead screw significantly improve machining accuracy and consistency compared to the previous model.

- Heavy-Duty Structure and Durability: Key components such as the spindle box, feed box, and tool post are made of high-quality materials and undergo strict quality inspection. The forced lubrication system and large-capacity cooling system effectively reduce wear and overheating, extending the service life of the machine.

- Easy Operation and Wide Adaptability: The user-friendly manual control system features clearly marked handwheels and dials for precise adjustment of spindle speed and feed rate. It supports processing of various common materials, including carbon steel, stainless steel, and high-strength alloy steel, meeting the diverse needs of different industries.

- Cost-Effective Investment: As a used upgraded lathe, the Baoji CS6150B offers exceptional cost performance. It provides the processing capabilities of a new heavy-duty precision lathe at a competitive price, enabling small and medium-sized enterprises to expand their production capacity and improve product quality without significant capital investment.

3,200.00$

| Item (项目) | Specification (规格) | Item (项目) | Specification (规格) |

|---|---|---|---|

| Model Number (型号) | CS6150B | Place of Origin (产地) | Baoji, China (中国宝鸡) |

| Machine Type (机床类型) | Heavy-Duty Horizontal Engine Lathe (重型卧式普通车床) | Brand Name (品牌) | Baoji Machine Tool (宝鸡机床) |

| Max. Swing Diameter Over Bed (最大加工直径) | Φ500mm | Max. Cutting Length (最大切削长度) | 1000mm / 1500mm / 2000mm / 3000mm (可选) |

| Spindle Bore (主轴通孔直径) | Φ80mm / Φ100mm (可选) | Spindle Speed Range (主轴转速范围) | 8-1400 rpm (24 级变速,变频可选) |

| Tool Post Stations (刀架工位) | 6-way Turret (六方刀架) / Optional Hydraulic Turret (可选液压刀架) | Feed Rate Range (进给量范围) | 0.02-2.0 mm/rev (纵向);0.04-3.8 mm/rev (横向) |

| Lead Screw Diameter (丝杠直径) | Φ40mm (高精度研磨丝杠) | Motor Power (电机功率) | 11 kW (主电机) + 1.5 kW (冷却泵电机) |

| Tailstock Quill Diameter (尾座套筒直径) | Φ75mm | Tailstock Quill Travel (尾座套筒行程) | 200mm |

| Max. Workpiece Weight (最大工件重量) | 1000 kg | Overall Dimensions (LWH) (外形尺寸) | 3300mm x 1650mm x 1750mm (示例,按切削长度调整) |

| Weight (重量) | Approx. 3200-4200 kg | Control System (控制系统) | Manual / Optional Semi-Automatic (手动 / 可选半自动) |

| Key Selling Points (核心卖点) | Upgraded Precision, Heavy-Duty Rigidity, Stable Performance, Wide Application, Low Maintenance | Warranty (质保) | 3 Months (Parts Only) |

| Machinery Test Report (机械检测报告) | Available Upon Request | Video Outgoing-Inspection (出货视频) | Available Upon Request |

| Cutting Material Range (切削材料范围) | Carbon Steel, Alloy Steel, Cast Iron, Stainless Steel, Copper, Aluminum, High-Strength Steel | Surface Roughness (表面粗糙度) | Ra ≤ 1.2 μm |

| Lubrication System (润滑系统) | Forced Lubrication (强制润滑) | Cooling System (冷却系统) | Large-Capacity Circulating Cooling (大容量循环冷却) |

| Spindle Bearing Type (主轴轴承类型) | High-Precision Tapered Roller Bearing (高精度圆锥滚子轴承) | Bed Structure (床身结构) | Reinforced Box-Type Cast Iron Bed (加强型箱式铸铁床身) |

Don’t miss your opportunity-our best machines go fast.