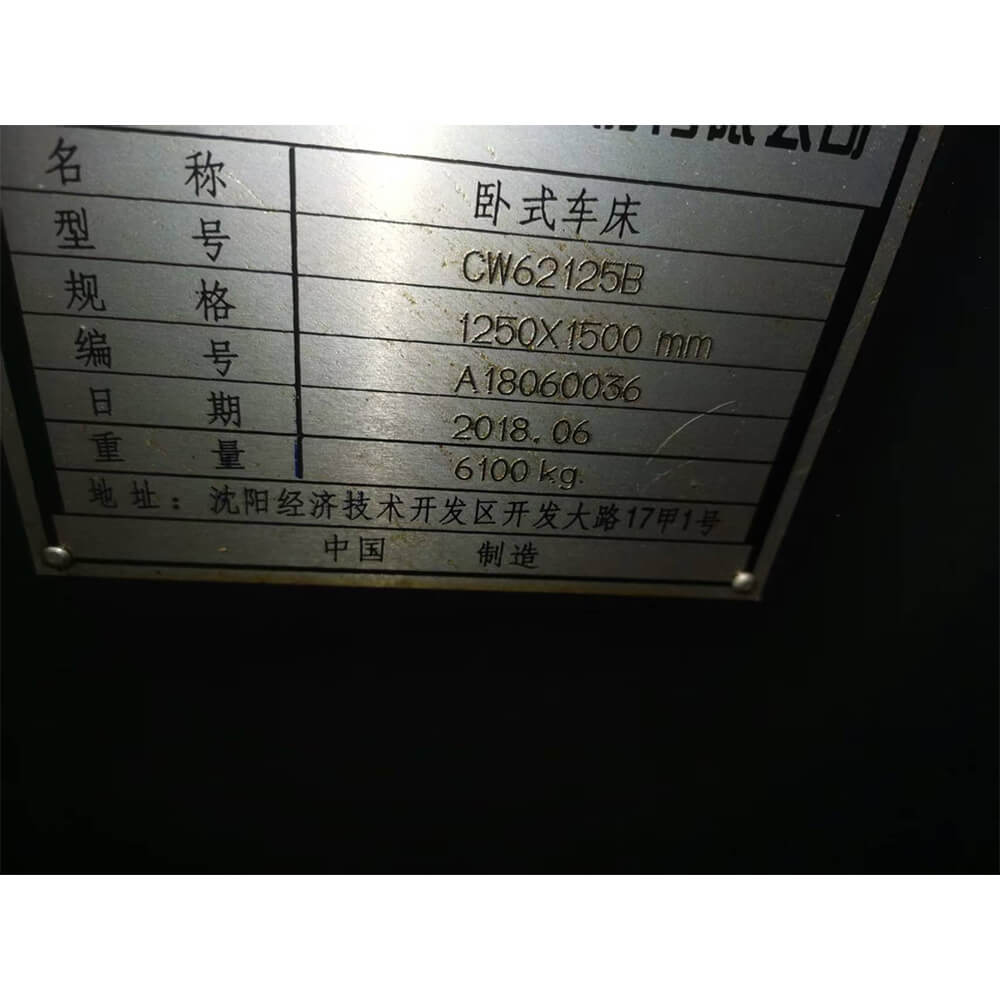

Shenyang CW62125B lathe

Core Application Scenarios

The Shenyang CW62125B lathe is a flagship ultra-large heavy-duty lathe from Shenyang Machine Tool, a century-old leader in China’s machine tool industry. Designed for extra-large and ultra-heavy rotating workpieces, it features enhanced load-bearing capacity and super rigidity, serving as core equipment in energy, shipbuilding, metallurgy and heavy machinery industries.

- Extra-Large Heavy Component Processing: With a maximum swing diameter of 1250mm and optional 220mm spindle bore, it specializes in turning large shafts, giant flanges and thick-walled cylinders—key parts for wind power generators, marine propellers and rolling mills. It efficiently processes HRC40 alloy steel with dimensional tolerance ±0.03mm.

- High-Precision Thread Machining: Equipped with ultra-precision ground lead screws, it accurately processes large-pitch threads (up to 40mm) of various types, suitable for heavy fasteners in offshore platforms and bridges.

- Batch Production of Large Parts: The 37kW main motor and hydraulic tool post (tool change time ≤4 seconds) ensure high efficiency. Its super-strong bed supports long-term heavy-load operation, fitting batch production of wind power main shafts.

- Mega-Equipment Overhaul: It repairs worn parts such as rolling mill rolls and ship shafts, minimizing downtime for key production equipment.

Batch Advantages of Equipment

- Super Load-Bearing & Rigidity: The integral cast iron bed undergoes multiple stress-relief treatments, maintaining stability during heavy cutting (cutting depth up to 30mm).

- Century-Brand Reliability: Mature manufacturing technology ensures a low annual failure rate (≤0.2%), with global spare parts supply.

- Efficient & Durable: Intelligent lubrication reduces wear, extending service life by 50%. The hydraulic tool post significantly cuts auxiliary time.

- Cost-Effective: As used equipment, it costs only 30%-45% of new models, enabling enterprises to acquire ultra-large processing capabilities at low cost.

3,900.00$

| Item (项目) | Specification (规格) | Item (项目) | Specification (规格) |

|---|---|---|---|

| Model Number (型号) | CW62125B | Place of Origin (产地) | Shenyang, China (中国沈阳) |

| Machine Type (机床类型) | Ultra-Large Heavy-Duty Horizontal Engine Lathe (超大型重型卧式普通车床) | Brand Name (品牌) | Shenyang Machine Tool (沈阳机床) |

| Max. Swing Diameter Over Bed (最大加工直径) | Φ1250mm | Max. Cutting Length (最大切削长度) | 3000mm / 5000mm / 8000mm (可选) |

| Spindle Bore (主轴通孔直径) | Φ180mm / Φ220mm (可选) | Spindle Speed Range (主轴转速范围) | 3-800 rpm (20 级变速,变频可选) |

| Tool Post Stations (刀架工位) | 6-way Hydraulic Turret (六方液压刀架) | Feed Rate Range (进给量范围) | 0.05-3.5 mm/rev (纵向);0.1-6.5 mm/rev (横向) |

| Lead Screw Diameter (丝杠直径) | Φ60mm (超精研磨丝杠) | Motor Power (电机功率) | 37 kW (主电机) + 5.5 kW (冷却泵电机) |

| Tailstock Quill Diameter (尾座套筒直径) | Φ140mm | Tailstock Quill Travel (尾座套筒行程) | 400mm |

| Max. Workpiece Weight (最大工件重量) | 10000 kg | Overall Dimensions (LWH) (外形尺寸) | 8000mm x 3000mm x 2800mm (示例,按切削长度调整) |

| Weight (重量) | Approx. 20000-32000 kg | Control System (控制系统) | Manual / Optional Semi-Automatic (手动 / 可选半自动) |

| Key Selling Points (核心卖点) | Century Brand, Super Load-Bearing, Ultra-Large Range, Stable Precision | Warranty (质保) | 3 Months (Parts Only) |

| Machinery Test Report (机械检测报告) | Available Upon Request | Video Outgoing-Inspection (出货视频) | Available Upon Request |

| Cutting Material Range (切削材料范围) | Carbon Steel, Alloy Steel, Cast Iron, Stainless Steel, Titanium Alloy | Surface Roughness (表面粗糙度) | Ra ≤ 1.6 μm |

| Lubrication System (润滑系统) | Intelligent Automatic Forced Lubrication (智能自动强制润滑) | Spindle Torque (主轴扭矩) | ≥15000 N・m (额定扭矩) |

| Bed Structure (床身结构) | Super-Strength Integral Cast Iron Bed (超强整体式铸铁床身) | Cooling System (冷却系统) | Dual-Circulation Large-Capacity Cooling (双循环大容量冷却) |

Don’t miss your opportunity-our best machines go fast.