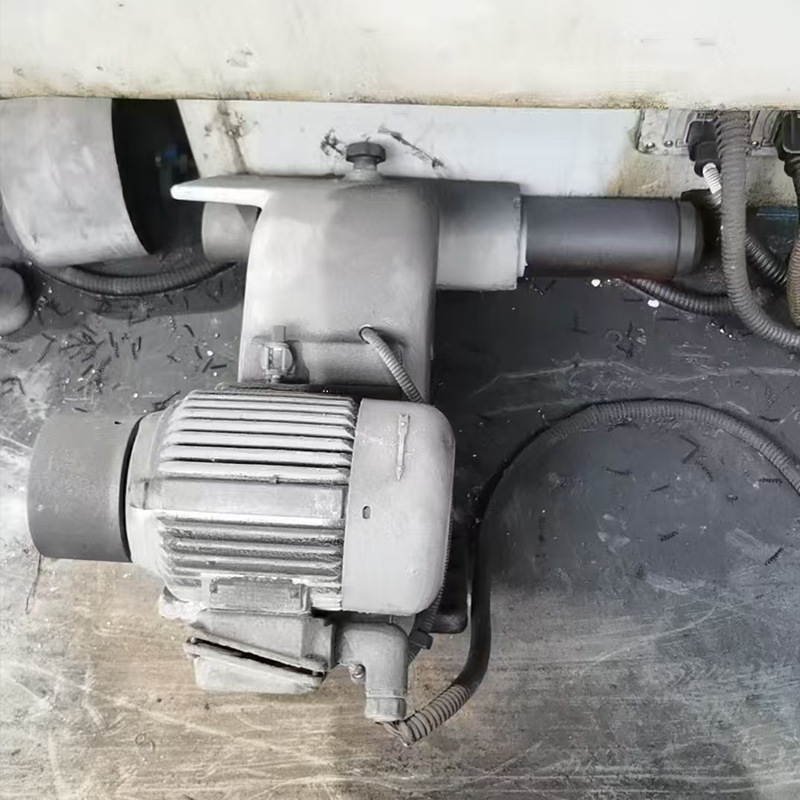

Universal cylindrical grinder M1432B

Core Application Scenarios

The M1432B is a high-performance universal cylindrical grinder, designed for precision grinding of external cylindrical surfaces, conical surfaces and stepped shafts of medium-to-large workpieces. It integrates high precision and versatility, widely used in bearing manufacturing, machinery parts processing, auto parts production and precision mold industries.

- Precision Component Grinding: Specializes in processing bearing rings, motor shafts, gear shafts and other core parts, achieving surface roughness Ra ≤ 0.08 μm and dimensional tolerance ≤ ±0.002 mm, meeting high-precision assembly standards.

- Multi-Shape Processing: The 0°-90° adjustable workhead supports both cylindrical and conical grinding, eliminating the need for multiple devices and reducing enterprise equipment investment.

- Medium Batch Production: Equipped with flexible feed control, it balances processing precision and efficiency, suitable for standardized parts production and customized component processing.

- Maintenance & Repair: Ideal for repairing worn precision shafts and sleeves, restoring their original dimensional accuracy and surface finish to extend service life of mechanical equipment.

Batch Advantages of Equipment

- High Precision & Stability: Adopts reinforced cast iron bed and precision spindle assembly, ensuring minimal vibration during grinding and consistent processing accuracy.

- Wide Processing Range: With max grinding diameter Φ320mm and multiple length options, it meets diverse processing needs of different industries.

- Easy Operation & Low Maintenance: User-friendly control panel with clear markings; automatic lubrication and cooling systems reduce component wear and maintenance costs.

- Cost-Effective: As used equipment, it costs only 30%-50% of new models, providing small and medium-sized enterprises with an affordable high-precision grinding solution.

4,000.00$

| Item (项目) | Specification (规格) | Item (项目) | Specification (规格) |

|---|---|---|---|

| Model Number (型号) | M1432B | Place of Origin (产地) | China (中国) |

| Machine Type (机床类型) | Universal Cylindrical Grinder (万能外圆磨床) | Brand Name (品牌) | Domestic Well-Known Brand (国内知名品牌) |

| Max. Grinding Diameter (最大磨削直径) | Φ320mm | Max. Grinding Length (最大磨削长度) | 1000mm / 1500mm / 2000mm (可选) |

| Workpiece Max. Weight (工件最大重量) | 150 kg | Spindle Speed (工件主轴转速) | 50-200 rpm (无级调速) |

| Grinding Wheel Size (砂轮尺寸) | Φ400×50×Φ127mm | Grinding Wheel Speed (砂轮转速) | 1800 rpm |

| Workhead Taper Angle Range (头架锥角范围) | 0°-90° (可调) | Tailstock Quill Diameter (尾座套筒直径) | Φ60mm |

| Feed Rate Range (进给量范围) | 0.001-0.05 mm/rev (横向);0.2-8 mm/rev (纵向) | Control System (控制系统) | Manual / Optional Semi-Automatic (手动 / 可选半自动) |

| Motor Power (电机功率) | 5.5 kW (主电机) + 1.1 kW (冷却泵电机) | Overall Dimensions (LWH) (外形尺寸) | 2800mm×1800mm×1900mm (示例,按磨削长度调整) |

| Weight (重量) | Approx. 2500-3800 kg | Key Selling Points (核心卖点) | High Precision, Wide Grinding Range, Stable Performance, Versatile |

| Warranty (质保) | 3 Months (Parts Only) | Machinery Test Report (机械检测报告) | Available Upon Request |

| Video Outgoing-Inspection (出货视频) | Available Upon Request | Grinding Material Range (磨削材料范围) | Carbon Steel, Alloy Steel, Bearing Steel, Stainless Steel |

| Surface Roughness (表面粗糙度) | Ra ≤ 0.08 μm | Dimensional Tolerance (尺寸公差) | ≤ ±0.002 mm |

| Lubrication System (润滑系统) | Automatic Circulating Lubrication (自动循环润滑) | Cooling System (冷却系统) | High-Pressure Circulating Cooling (高压循环冷却) |

Don’t miss your opportunity-our best machines go fast.