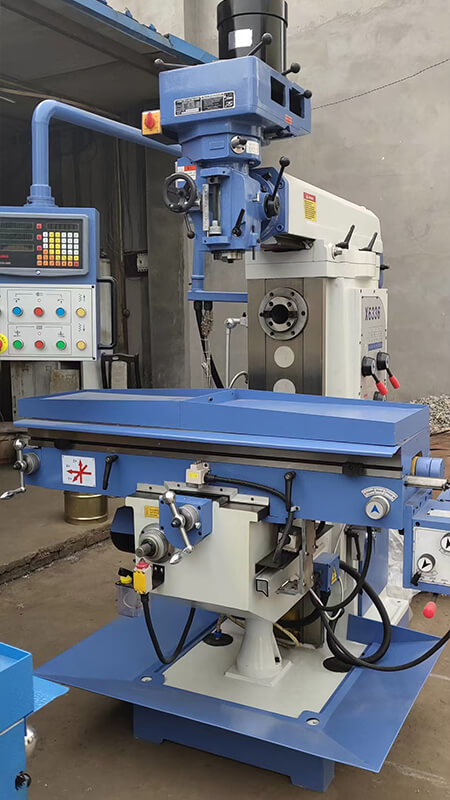

Milling Machine X6336

| Product Attribute | Details |

|---|---|

| Model | X6336 |

| Spindle Type | Vertical/horizontal dual spindle |

| Spindle Taper | Vertical spindle: ISO 40; Horizontal spindle: Morse Taper 5 (MT5) |

| Spindle Speed Range | Vertical: 78-6980 r/min; Horizontal: 60-1800 r/min |

| Spindle Power | Vertical: 3.7kW; Horizontal: 4kW |

| Table Size | 1250×360mm (Length×Width) |

| Table Travel | X-axis (longitudinal): 1000mm; Y-axis (transverse): 360mm; Z-axis (vertical): 400mm |

| Max Table Load | Approximately 350kg |

| Feed Rate Range | 10-1000mm/min (adjustable, multiple gears optional) |

| Machine Weight | Approximately 2500-3000kg |

| Overall Dimensions | Approximately 2200×1800×2100mm (Length×Width×Height) |

| Power Supply | 380V/50Hz (three-phase AC) |

| Additional Features | Optional 3-axis digital readout (DRO), automatic lubrication system, cooling system |

4,300.00$

Powerful and Versatile Machining Capabilities

The X6336 can perform a diverse range of operations, including milling, drilling, boring, reaming, and tapping on various materials such as steel, cast iron, and non - ferrous metals. With its dual - function vertical and horizontal milling spindles, it offers enhanced flexibility. For instance, the vertical spindle is well - suited for precision finishing and semi - finishing operations, while the gear - driven horizontal spindle can handle heavy - duty cutting tasks with ease. This makes it an ideal choice for manufacturing a wide variety of industrial parts, from small, intricate components to larger, more robust pieces.

High - Precision Performance

Equipped with a Taiwan - sourced high - speed turret head, the X6336 ensures excellent precision. The turret head can rotate up to ± 90° in the vertical plane, enabling complex angled cuts. The spindle bearings are pre - pressed precision angular contact ball bearings, which, combined with a spindle made of high - quality chromium - molybdenum alloy, provide high rigidity and outstanding machining accuracy. The table surface undergoes quenching and precision grinding processes, resulting in not only good precision but also remarkable wear resistance. Additionally, the option to install a 3 - axis digital display, accurate to 0.01 mm, further enhances the machine's precision capabilities, allowing for more accurate and consistent machining.

Robust and Stable Structure

The machine features a rigid, heavy - duty frame based on a proven knee - and - column design. The use of high - strength cast iron in the fuselage and main components ensures micro - structure stability, which is crucial for maintaining the machine's stability during long - term use. The guideways and gears are hardened and ground, reducing friction and wear, and improving the overall durability of the machine. The table, with a size of 1250×360 mm (for example), can support a maximum load of 350 kg (approx.), and its X - direction travel can reach up to 1000 mm (varies by model), providing a large working area for various workpiece sizes.

Flexible Speed and Feed Adjustments

The X6336 offers a wide range of spindle speeds. For example, the vertical spindle may have a speed range of 78 - 6980 r/min, while the horizontal spindle could range from 60 - 1800 r/min. This wide speed variation allows operators to select the most appropriate speed for different materials and machining requirements. The machine also has adjustable feed rates. The work table feed, driven by a servo motor in some models, offers good accuracy, low noise, and ease of operation. There are multiple feed directions that can be easily selected with a single lever, providing flexibility in machining operations.

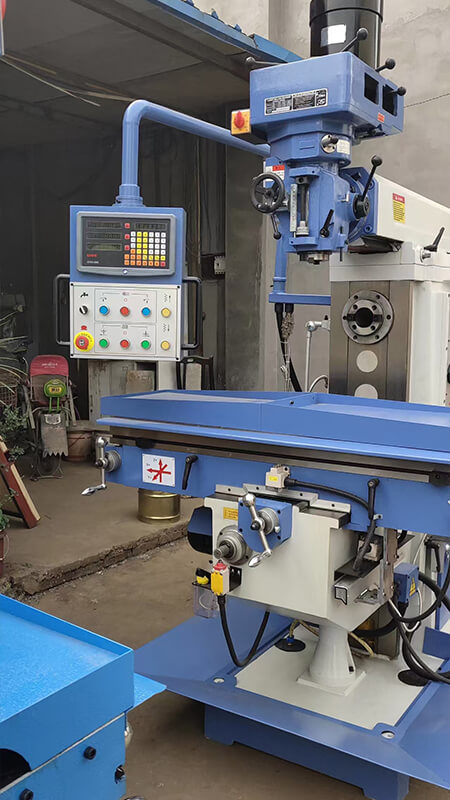

User - Friendly Operation

The control panel of the X6336 is designed for simplicity and ease of use. All the necessary controls are grouped together, making it convenient for operators to adjust parameters such as spindle speed, feed rate, and table movement. In some models, the independent centralized operation panel further enhances the clarity of operation. Additionally, the option to install a digital readout (DRO) system, which is easy to read and interpret, helps operators to accurately set and monitor the machining process. The machine may also come with features like an automatic centralized oil lubrication system, reducing the need for frequent manual lubrication and ensuring smooth operation of moving parts.

Don’t miss your opportunity-our best machines go fast.