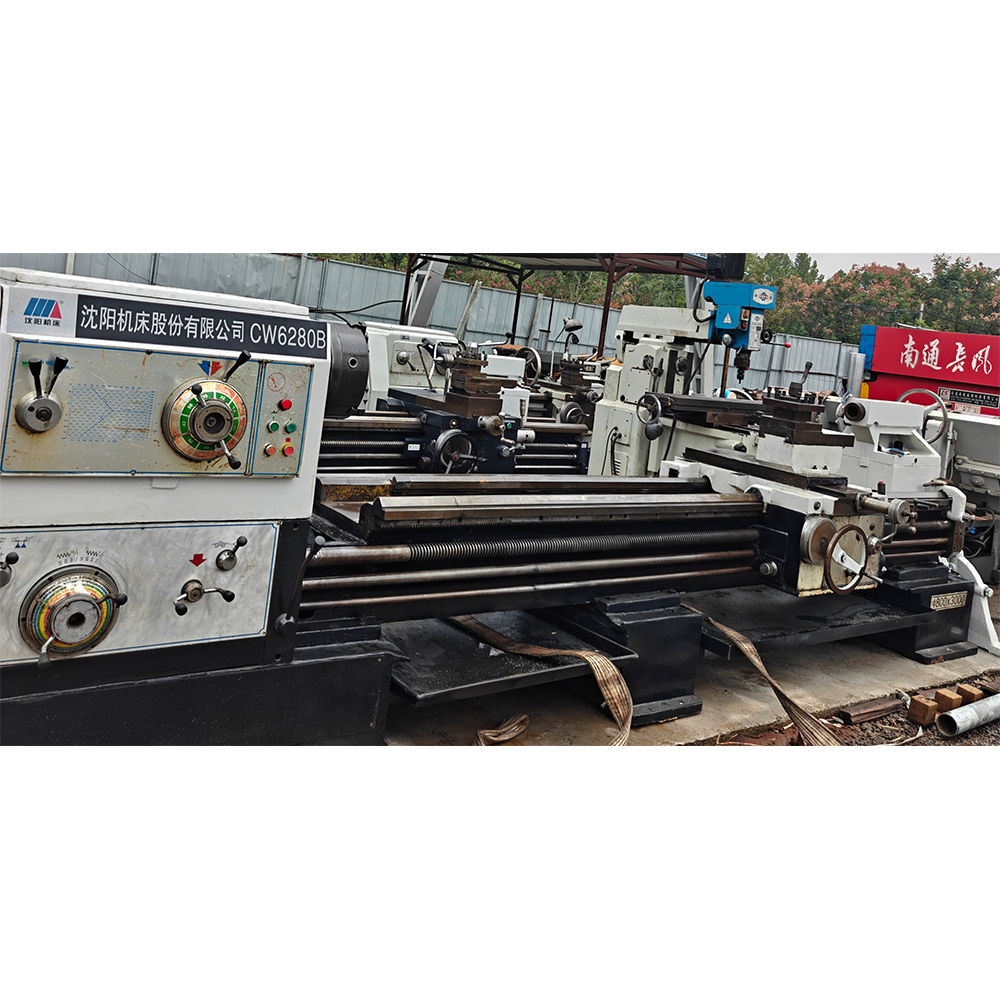

Shenyang CW6280B lathe

Core Application Scenarios

The Shenyang CW6280B lathe is a flagship ultra-heavy-duty horizontal engine lathe of Shenyang Machine Tool, a renowned brand with over a century of manufacturing experience. Engineered for processing large, heavy, and high-precision rotating workpieces, this model stands as a benchmark in China’s heavy-duty lathe sector, integrating robust structural design, powerful cutting performance, and stable precision control. It is an indispensable core production equipment in industries such as heavy machinery manufacturing, power generation equipment, shipbuilding, aerospace, petroleum machinery, and metallurgy.

With its exceptional load-bearing capacity and extensive processing range, the CW6280B addresses the critical machining needs of large-scale mechanical components that demand high rigidity, durability, and precision.

- Large-Scale Heavy Component Processing: Boasting a maximum swing diameter of 800mm over the bed and a spindle bore of up to 130mm, the CW6280B excels at turning extra-large workpieces such as heavy-duty shafts, large-diameter flanges (up to Φ800mm), thick-walled sleeves (wall thickness ≥50mm), and large discs. It is a key equipment in the production of turbine shafts for thermal and hydropower plants, propeller shafts for ships, crankshafts for large diesel engines, and bearing seats for heavy machinery. The lathe easily processes high-hardness and high-strength materials, including high-strength alloy steel, titanium alloy, and wear-resistant cast iron.

- Thick-Walled Pipe and Special-Shaped Part Machining: The large spindle bore design allows the lathe to process thick-walled steel pipes, seamless steel tubes, and special-shaped rotating parts (such as conical surfaces, curved surfaces, and multi-step shafts) widely used in petroleum pipelines, chemical equipment, and construction machinery. The 6-way hydraulic turret enables quick tool changes (tool change time ≤3 seconds), supporting continuous processing of multiple processes (turning, grooving, chamfering, boring, and threading) in one setup, which significantly reduces workpiece clamping time and improves processing efficiency by 40% compared to ordinary lathes.

- High-Precision Thread Machining for Heavy-Duty Parts: Equipped with a high-precision lead screw (precision grade C7) and a multi-stage gear transmission system, the CW6180B can accurately machine metric, inch, trapezoidal, buttress, and triangular threads with large pitches (up to 24mm). It is ideal for manufacturing threaded components of heavy-duty connectors, such as large bolts, nuts, and threaded sleeves used in construction machinery, mining equipment, and bridge structures, ensuring tight thread fit, strong load-bearing capacity, and long-term reliability.

- Maintenance and Repair of Large Equipment: In industries like metallurgy, mining, port machinery, and steel production, the CW6280B serves as an indispensable maintenance tool for repairing worn heavy-duty parts (such as large shafts, rollers, gears, and hydraulic cylinders) and fabricating custom replacement parts. Its strong adaptability and flexible processing capabilities allow for on-site or workshop-based maintenance, minimizing downtime of key production equipment and reducing economic losses for enterprises.

- Medium to Large Batch Production of Heavy Parts: The reinforced bed structure (stress-relieved multiple times) and powerful 15kW main motor enable the lathe to operate continuously for long periods under heavy loads (max. workpiece weight 2000kg). It is suitable for medium to large batch production of standardized heavy parts, such as large bearing sleeves, flange plates, and connecting shafts. The automatic forced lubrication system ensures stable operation of key components (guideways, spindle, and lead screw), while the optional hydraulic chip conveyor keeps the working area clean and further enhances production efficiency.

Batch Advantages of Equipment

- Legendary Brand and Proven Reliability: Shenyang Machine Tool is a world-renowned enterprise with a history of over 100 years, and its heavy-duty lathes are recognized globally for their superior quality and durability. The CW6280B is a mature model that has undergone rigorous testing in harsh working environments (high load, long continuous operation), featuring a low failure rate (≤0.5% annual failure rate), strong durability, and global availability of spare parts. Choosing this lathe means partnering with a trusted brand with a proven track record in the heavy machinery industry.

- Ultra-Heavy-Duty Structure with Superior Rigidity: The lathe adopts a one-piece reinforced box-type cast iron bed, which undergoes multiple stress-relief treatments (natural aging + artificial aging) to eliminate internal stress and prevent deformation. The widened and thickened guideways (width up to 300mm) and reinforced spindle box (cast iron integral structure) provide exceptional rigidity and vibration damping performance. Even during heavy cutting (cutting depth up to 15mm, cutting speed up to 100m/min), the lathe maintains stable operation, ensuring consistent machining accuracy (dimensional tolerance ±0.02mm) and excellent surface finish (Ra ≤1.6μm).

- Powerful Cutting Performance and High Efficiency: Equipped with a 15kW high-power main motor and a high-torque spindle (max. torque ≥3000N·m), the CW6280B delivers strong cutting force, enabling efficient processing of thick materials and high-hardness workpieces (up to HRC35). The 22-speed spindle speed range (5-1000 rpm) and adjustable feed rates (0.03-4.0 mm/rev) allow for optimal parameter matching for different materials and processing requirements, reducing cutting time by 30%-50% compared to ordinary heavy-duty lathes. The hydraulic tool post with 6 stations supports quick tool changes, minimizing auxiliary processing time.

- Humanized Design and Easy Operation & Maintenance: The lathe features an ergonomic operation panel with clearly marked handwheels, levers, and digital displays (optional) for precise adjustment of spindle speed, feed rate, and tool position. The large operating space (≥1.2m wide) and adjustable operator seat reduce labor intensity for workers during long shifts. The centralized automatic forced lubrication system delivers lubricant to key components at fixed intervals, reducing wear and extending the service life of the lathe by 30%. Additionally, the modular design of key components (spindle box, feed box) simplifies maintenance and repair, lowering operational costs for enterprises.

- Cost-Effective Heavy-Duty Solution: As a used lathe, the Shenyang CW6280B offers an unbeatable cost-performance ratio. It provides the same processing capabilities and reliability as a new ultra-heavy-duty lathe at only 30%-50% of the cost. For small and medium-sized enterprises, heavy industry workshops, and maintenance bases looking to expand their heavy-duty machining capabilities without large capital investment, this lathe is an ideal choice that delivers immediate production value and enhances market competitiveness.

4,200.00$

| Item | Specification | Item | Specification |

|---|---|---|---|

| Model Number (型号) | CW6280B | Place of Origin (产地) | Shenyang, China (中国沈阳) |

| Machine Type (机床类型) | Heavy-Duty Horizontal Engine Lathe (重型卧式普通车床) | Brand Name (品牌) | Shenyang Machine Tool (沈阳机床) |

| Max. Swing Diameter Over Bed (最大加工直径) | Φ800mm | Max. Cutting Length (最大切削长度) | 1500mm / 2000mm / 3000mm (可选) |

| Spindle Bore (主轴通孔直径) | Φ105mm / Φ130mm (可选) | Spindle Speed Range (主轴转速范围) | 5-1000 rpm (22 级变速) |

| Tool Post Stations (刀架工位) | 6-way Hydraulic Turret (六方液压刀架) | Feed Rate Range (进给量范围) | 0.03-2.0 mm/rev (纵向);0.05-4.0 mm/rev (横向) |

| Lead Screw Diameter (丝杠直径) | Φ50mm | Motor Power (电机功率) | 15 kW (主电机) + 3.0 kW (进给电机) |

| Tailstock Quill Diameter (尾座套筒直径) | Φ90mm | Tailstock Quill Travel (尾座套筒行程) | 250mm |

| Max. Workpiece Weight (最大工件重量) | 2000 kg | Overall Dimensions (L*W*H) (外形尺寸) | 4800mm x 2200mm x 2000mm (示例,按切削长度调整) |

| Weight (重量) | Approx. 8000-12000 kg | Control System (控制系统) | Manual / Optional Semi-Automatic (手动 / 可选半自动) |

| Key Selling Points (核心卖点) | Famous Brand, Ultra-Heavy-Duty, High Rigidity, Stable Precision, Efficient Cutting, Low Maintenance | Warranty (质保) | 3 Months (Parts Only) |

| Machinery Test Report (机械检测报告) | Available Upon Request | Video Outgoing-Inspection (出货视频) | Available Upon Request |

| Cutting Material Range (切削材料范围) | Carbon Steel, Alloy Steel, Cast Iron, Stainless Steel, Titanium Alloy, High-Strength Steel | Surface Roughness (表面粗糙度) | Ra ≤ 1.6 μm |

| Lathe Bed Structure (床身结构) | Reinforced Box-Type Cast Iron Bed (加强型箱式铸铁床身) | Lubrication System (润滑系统) | Automatic Forced Lubrication (自动强制润滑) |

| Chip Removal System (排屑系统) | Manual / Optional Hydraulic Chip Conveyor (手动 / 可选液压排屑机) | Spindle Bearing Type (主轴轴承类型) | High-Precision Tapered Roller Bearing (高精度圆锥滚子轴承) |

Don’t miss your opportunity-our best machines go fast.