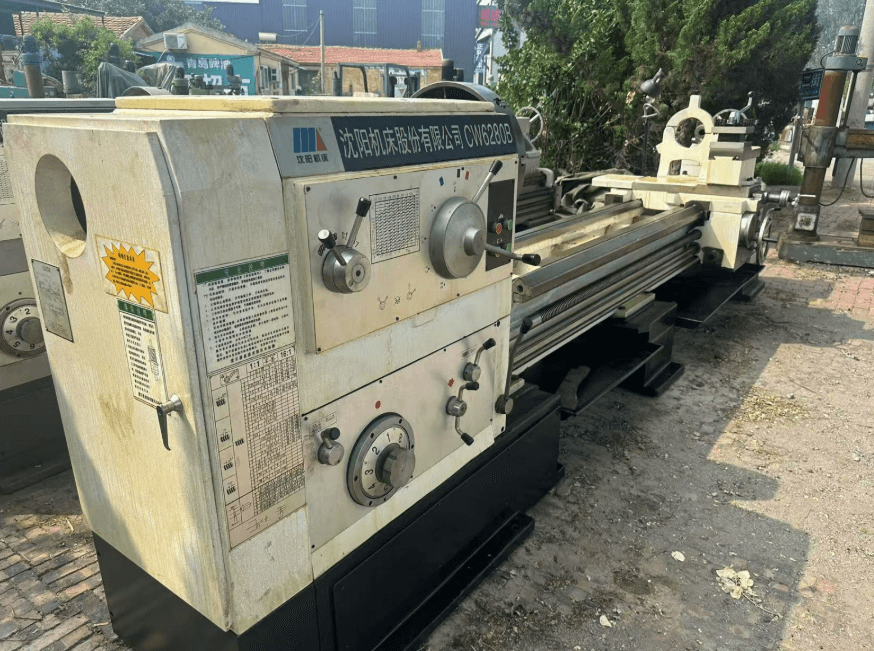

Shenyang CW6280B Used Lathe

| Product Attribute | Description |

|---|---|

| Model | Shenyang Machine Tool CW6280B |

| Machine Type | Lathe |

| Machining Capabilities | – Turning internal/external cylindrical surfaces, end faces, and conical surfaces – Processing large-diameter or irregular parts with saddle – Cutting metric, imperial, module, diametral pitch, and circular pitch threads – Drilling, reaming, and oil groove drawing |

| Structural Features | – Medium-frequency quenched guide rails (high hardness and durability) – Rational structure, stable operation, and low noise – Larger spindle bore (facilitating special-shaped parts and long shafts) |

| Machining Precision | – Dimensional accuracy up to IT7 – Surface roughness up to Ra1.6 |

| Processing Range | – Maximum swing diameter over bed: 800mm – Maximum center distance options: 750mm, 1000mm, 1500mm, 2000mm, 3000mm, 4000mm, 5000mm, 6000mm, 7000mm, 8000mm |

| Operational Features | – Apron with rapid-feed design (single-handle operation) – Hydraulically controlled spindle (forward/reverse/braking, sensitive and reliable) – Optional manual or foot brake – Tailstock with dial and scale for direct reading |

| Lubrication & Cooling | – Headstock and feed box: Oil-pump shower lubrication (reduces wear) – Cooling system: Water-electricity separation (safe, effective for cutting area cooling) |

| Optional Configurations | – Spindle bore options: 100mm, 130mm (special order) – Spindle nose types: C11, D11 (D11 for imperial/system special orders) – Main motor power: 11kW (15kW, 22kW available on special order) |

8,000.00$

- Wide - ranging Machining Capabilities: It can perform various turning operations, such as turning the internal and external cylindrical surfaces, end faces, and conical surfaces of parts. The lathe with a saddle can be used to turn large - diameter or deformed parts. According to user requirements, it can be equipped with a metric or imperial lead screw, and can complete the turning of metric, imperial, module, diametral pitch and circular pitch threads, as well as drilling, reaming and oil groove drawing.

- Excellent Structural Performance: The guide rails are quenched by medium - frequency, with high hardness and durability, which can extend the service life of the machine tool. The machine has a reasonable structure, runs smoothly, and has a low noise level. The spindle hole is larger than that of similar machine tools, which is beneficial to processing some special - shaped parts and passing through long - shaft workpieces.

- High - precision Machining: The size accuracy of the parts processed on this machine can reach IT7 level, and the surface roughness can reach Ra1.6 level, which can meet the processing requirements of most general - precision parts.

- Large Processing Range: The maximum swing diameter of the workpiece over the bed is 800mm, and the maximum distance between centers can be 750mm, 1000mm, 1500mm, 2000mm, 3000mm, 4000mm, 5000mm, 6000mm, 7000mm or 8000mm, which can meet the processing of workpieces of different sizes.

- Convenient Operation: The apron has a rapid - design, which can be operated with a single handle, which is simple and convenient. The forward, reverse and braking of the spindle are all hydraulically controlled, with sensitive response and reliable action. It can be optionally equipped with a manual brake or a foot brake to meet the operation habits of different users. The tailstock is equipped with a dial and scale for direct reading, which is convenient for accurate positioning during processing.

Don’t miss your opportunity-our best machines go fast.